Description

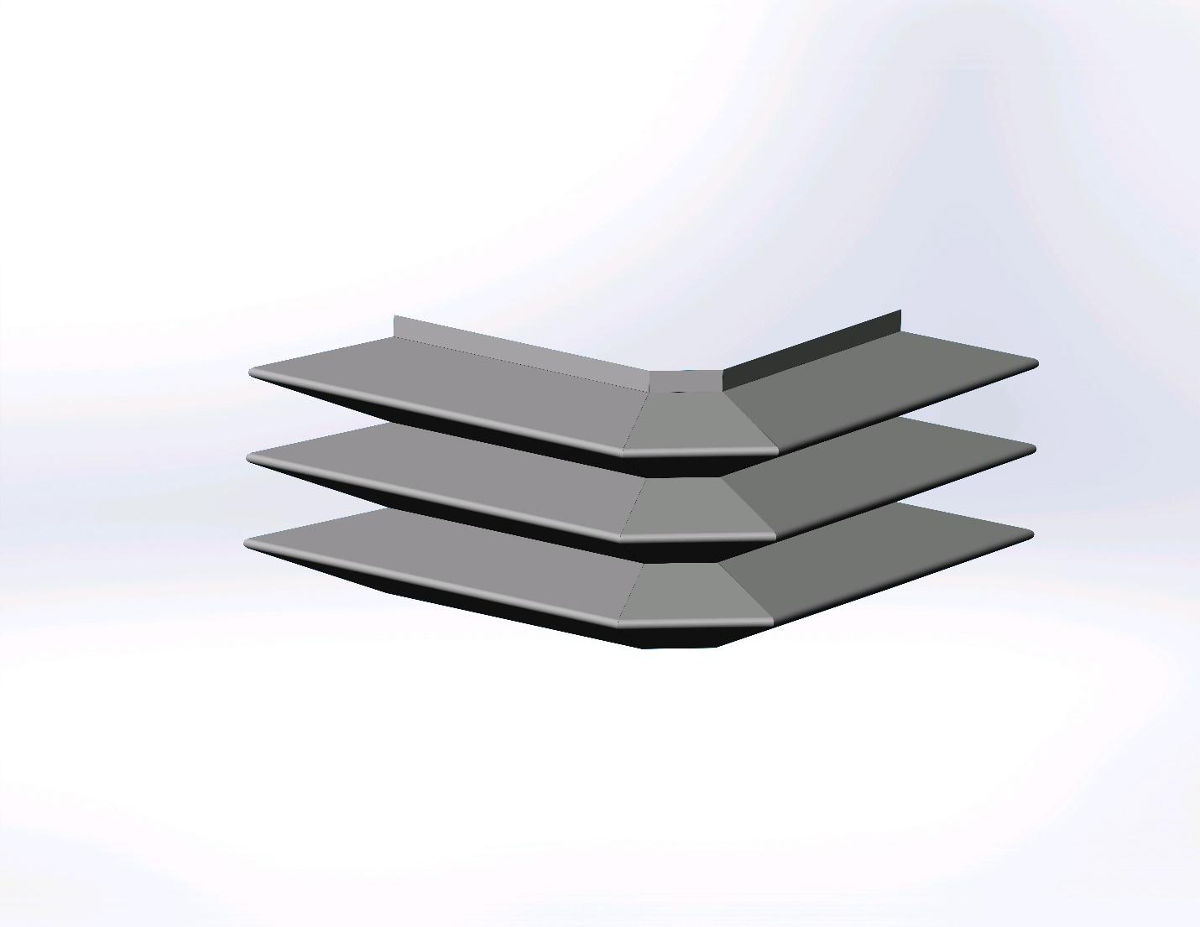

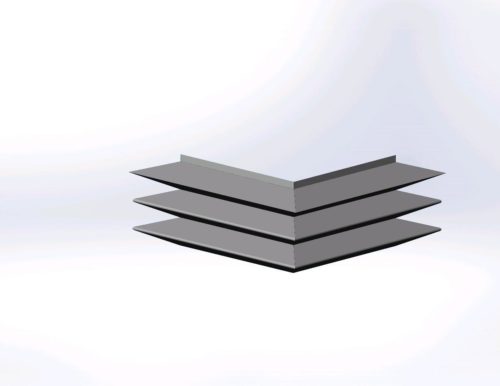

The double miter is not as common as the single miter corner expansion joint, likely due to the added cost to manufacture. However, by using a double mitered rectangular joint you are significantly reducing stresses on the corner welds, which serves to meaningfully enhance useful service life. This can be especially important in critical applications where down time can result in catastrophic losses.

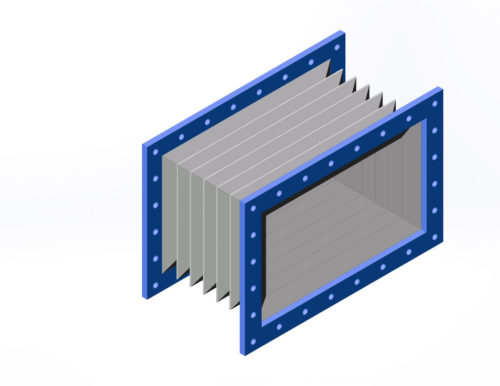

Like all of our rectangular expansion joints, your flanged ends will be laser cut on our 6000kW machine to ensure incredible accuracy and unparalleled fitment in the field. Angle flanges and weld ends are options as well. Other options include internal flow liners, external shrouds as well as tie rods, control rods and limit rods. DME has the capability to build any number of unique sizes and shapes to meet your specific needs and in various in-stock alloys. Give us a call to help you with your next square or rectangular expansion joint project!